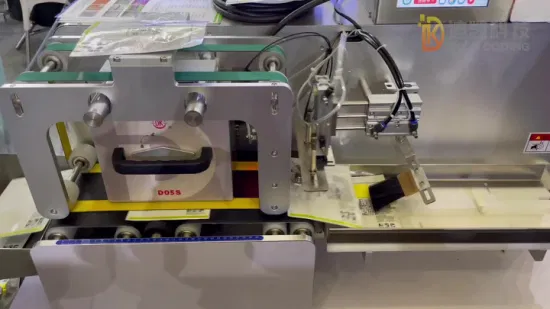

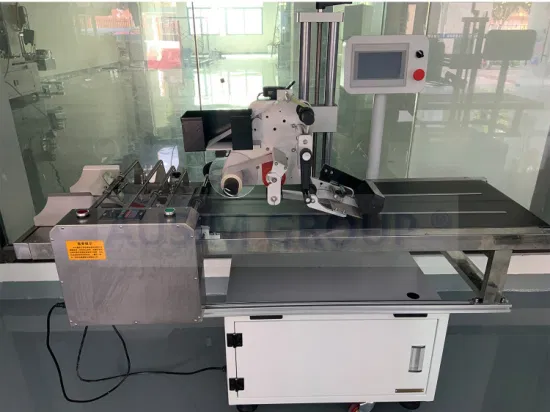

Automatic Paging Labeling Machine for Hang Tag Paper Bag Card Top Surface Sticker Labeller

Overview Product Description Automatic paging labeling machine for hang tag paper bag card top surface sticker labeller

Send your inquiryDESCRIPTION

OverviewBasic Info.

| Classification | Automatic Vertical Round Bottle Labeling Machine |

| Packaging Material | Paper Bags,Cards, Cases and Bags with Thin Surface |

| Packaging | Paper Bags,Cards, Cases and Bags Labeler |

| Function | Flat Surface Labeling Machine |

| Suitable Bottle Type | Paper Bags,Cards, Cases and Bags with Thin Surface |

| Label Inner Diameter | 76mm |

| Label Roll out Diameter | 300mm |

| Label Type | Paper or Plastic Sticker |

| Application Scope | Cosmetics,Chemical, Pharmaceutical |

| Power Supply | 220V |

| Labeling Speed | 40-100PCS/Min |

| Material | Stainless Steel |

| Transport Package | Wooden Case |

| Specification | paper bags, cards, cases and bags labeler |

| Trademark | YETO |

| Origin | Guangdong. China |

| HS Code | 8422309090 |

| Production Capacity | 100sets Per Month |

Product Description

Product DescriptionAutomatic paging labeling machine for hang tag paper bag card top surface sticker labeller

This automatic labeling machine is suitable for all kinds of paper bags,cards, cases and bags with thin surface label products,with paging mechanism, which can automatically separate products, transmit labels and reduce manpower.

Application:1.Application industry: widely used in food, toys, daily chemicals, electronics, medicine, hardware, plastics, stationery, printing and other industries;2.Applicable labels: paper labels, transparent labels, metal labels, etc.3.Application examples: carton labeling, SD card labeling, electronic accessories labeling, carton labeling, flat bottle labeling,ice cream box labeling, foundation box labeling, etc.Product Parameters

| Labeling speed | 40 ~ 120 pieces / minute (related to product size) |

| Applicable power supply | 220V/50HZ |

| Machine size | about 2000mm × 700mm × 1470mm |

| Machine weight | 200kg |

| Labeling accuracy | ±1mm |

| Separated bag size | ≤200mm |

| Labeling width | ≤130mm |

FAQ

1. What about your factory?One of our factory is located in Guangzhou and another one is in Jiangsu province. We have more than 100 workers in our factory,over 20 years experience on cosmetic machinery making and more 15 years experience for installing overseas.2.What you can do for us if the machine is out of your catalogue?Factory as we are ,we have ability to manufacture machines based on your drawing or mind.3.What do we do if we encounter problem about the machine ?Showing us the picture or video of the problem. If the problem can be solved by your workers, we will send you solution by video or pictures. If the problem out of your control, our engineer will be sent to your factory (customer will pay the fee during the trip).4. What about after sale service?We provide two years warranty period for large equipment, such as hydraulic homogenizer ,vacuum emulsifying mixer etc. One year for small filling machines, such as semi-automatic labeling machine series.We provide wearing parts(not caused by improper operating) for free within the warranty period(except delivery fee).5 How to finish installing?Our engineer can be sent to your country. but customer should pay the air tickets. besides, customer should arrange the accommodation for them during the trip.

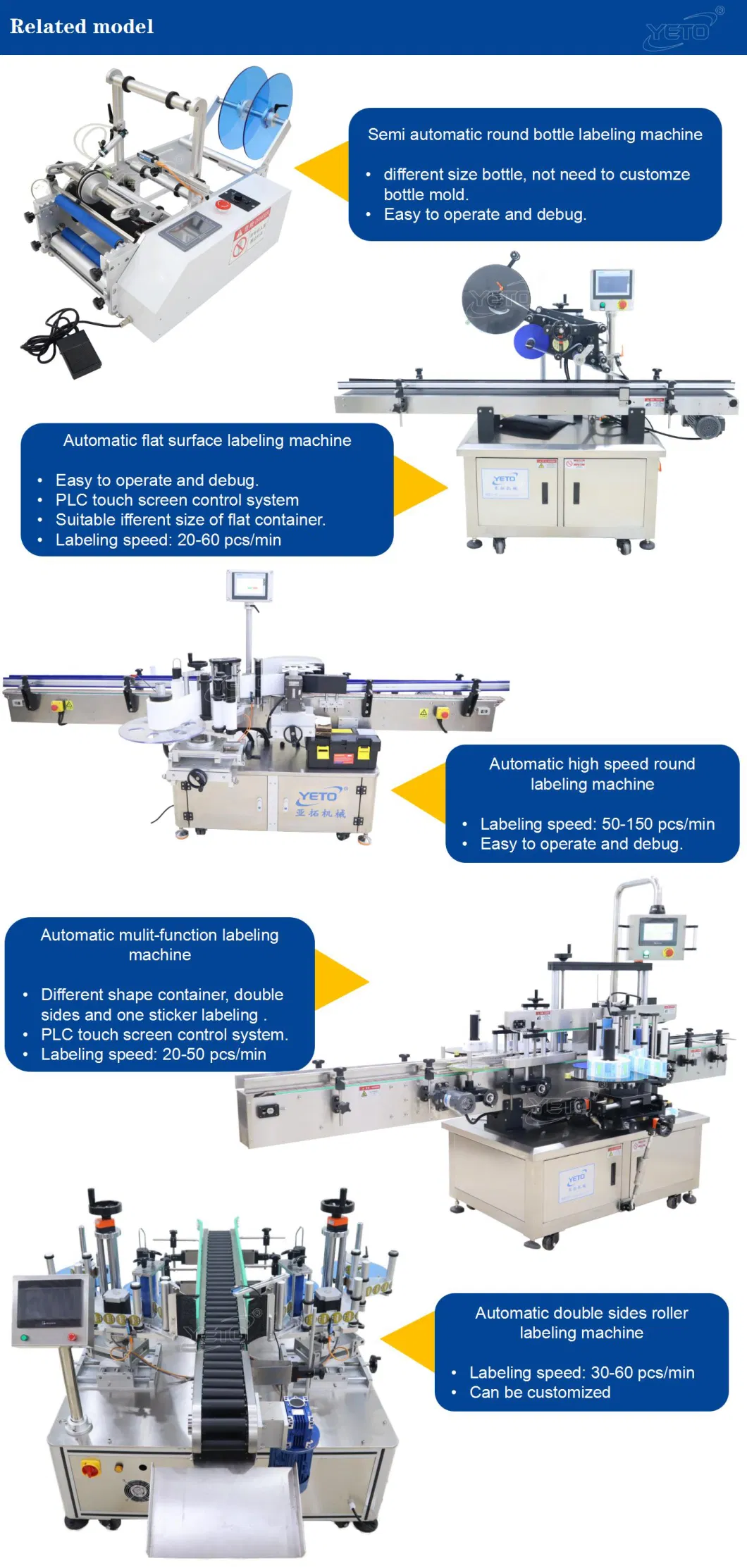

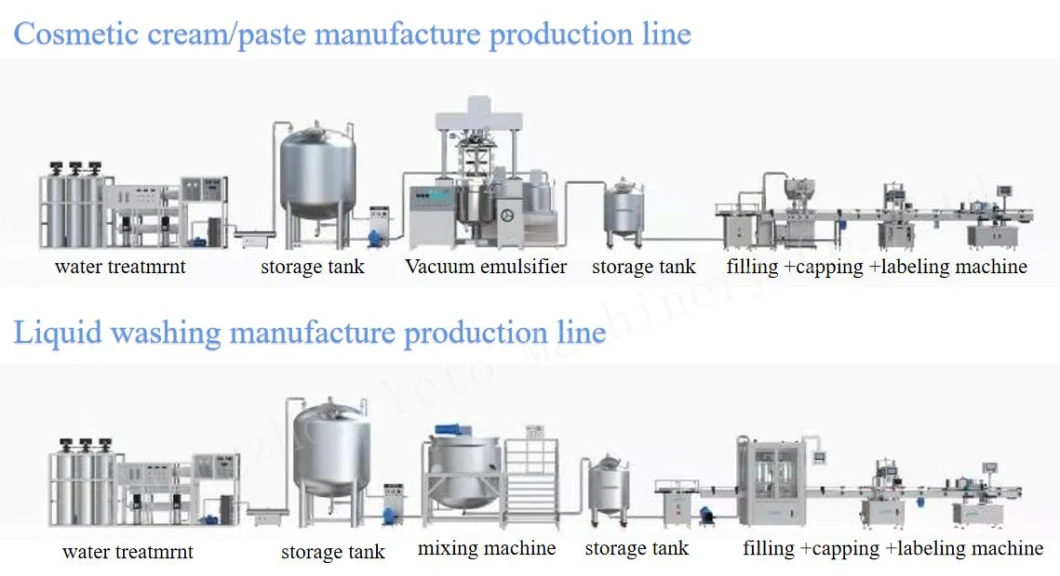

Company ProfileRelated Products