Chb38s Rotary Encoder Series Ec11 Encoder

Product DescriptionRotary Encoder SeriesRotary encoders are high tech sensors with a combination of optical, mechanical,

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | CHB38S |

| Package | SMD |

| Installation Form | Axle Sleeve Type |

| Brand | C-Lin |

| Axonia | Servo Installation Type |

| Transport Package | Standard Export Packing |

| Trademark | C-lin |

| Origin | China |

| HS Code | 8543709990 |

| Production Capacity | 5000PCS/Month |

Product Description

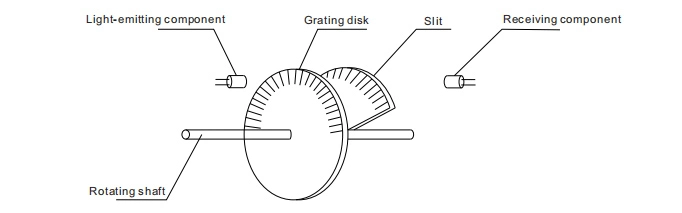

Product DescriptionRotary Encoder SeriesRotary encoders are high tech sensors with a combination of optical, mechanical, electrical precision technology to measure displacement and angle.

Main Features:

small size, various types, complete function, high frequency response, high resolution, low power consumption, stable performance, reliable and long life.

Specification

| CHB38S series | |

| Model | CHB38S-N/E/F/L-(5,10,50,60,100,200,300,360,400,500,600,800,1000,1024,1200,2000,2500) |

| Main size | External diameter:φ38mm; Shaft diameter:φ6mm |

| Working power | DC5V-24V |

Output mode | N: Open-collector output (NPN) |

| E: Voltage output | |

| F: Complementary output | |

| L: Drive output | |

| Pulse output | 5,10,50,60,100,200,300,360,400,500,600,800,1000,1024,2000,2500 |

| Output phase | A B Z or A B Z -A -B -Z |

| Termination mode | G:Side entry cable |

Application | Bending machines, solar cutting machines, glass machinery and food packaging industry |

Working principle

Outline size

Precaution

1). This product is consists of high-precision parts, be sure to handle with utmost care, do not drop.

2). When mounting this product, if decentering tolerance or declination tolerance is too big, may

result in reduce its working life.

3). Make sure that the product is free from impact, vibration, corrosion, high magnetic field, high

temperature, high humidity and acid-alkaline environment.

4). Unnecessary pulses are output when turn ON or OFF, be sure to turn ON the peripheral devices

connect to the encoder 0.5S after turning ON the encoder, and turn OFF the peripheral devices

0.5S before turning OFF the encoder.

5). After wiring the cable with the encoder securely, do not pull the cable with 29.4N or more.

6). If it is near to high voltage line or power supply cable, please use cable tube to cover the wires.

7). When wiring the cable, be sure no short connect between each cable, do not make mistakes in the

wiring, otherwise the encoder may be damaged.

It is suggest to make proper insulation for the cable which is not required for connection

9. Precaution

8). Shielded cable should be proper grounded.

9). Do not disassembly the product